Microwave Technology in Recycling

is not just a novel concept; it’s a transformative force in the recycling field. Recent collaborations have brought this technology to the forefront of sustainable solutions. Promising to change the recycling landscape by making processes more efficient and environmentally friendly, microwave technology is emerging as an exciting option. In this post, we’ll explore two groundbreaking examples of how this technology is being utilized in the recycling sector.

Asahi Kasei and Microwave Chemical: A Collaborative Leap Forward

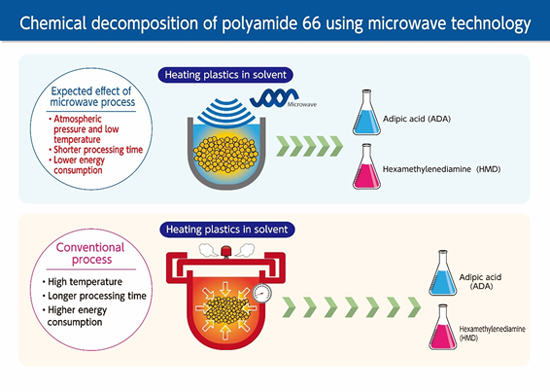

In April 2023, Asahi Kasei and Microwave Chemical joined forces to initiate a project aimed at commercializing the chemical recycling of polyamide 66 (PA66, also known as nylon 66) using microwave technology. This microwave-based process involves the use of microwaves to break down PA66 into monomers, which can then be used to manufacture new PA66.

This joint demonstration project focuses on recycling scraps from manufacturing and post-use waste material of PA66, commonly used in airbags and automobile parts. By utilizing microwave technology, they hope to achieve high yield with low energy consumption.

Asahi Kasei, a long-standing producer of fossil fuel–derived intermediate products, and Microwave Chemical, a pioneer in achieving carbon neutrality, are working together to create a sustainable manufacturing process. This initiative intends to reduce greenhouse gas (GHG) emissions compared to conventional manufacturing processes.

With a small-scale demonstration trial planned for fiscal 2024 and potential commercialization by 2025, this partnership represents an exciting step towards a circular economy in the PA66 value chain.

gr3n’s Groundbreaking Approach in Spain

gr3n, in partnership with Intecsa Industrial, has announced its intention to construct a “First-of-a-Kind” manufacturing facility in Spain for the microwave-assisted depolymerization of PET (polyethylene terephthalate). With the capacity to produce 40,000 tons of virgin-like PET, gr3n’s unique chemical recycling technology will handle PET from various industries, including textile waste.

Their Microwave Assisted Depolymerization (MADE) technology holds the potential to transform how PET is recycled worldwide, closing the loop for hard-to-recycle PET applications. The first industrial-scale MADE PET recycling plant will process various PET waste to produce virgin PET chips, saving nearly 2 million tons of CO2 during its operating life.

This pioneering project underscores the future of recycling, moving from a linear to a circular system and potentially achieving textile-to-textile or even textile-to-bottle recycling.

Conclusion

Microwave technology in recycling is not merely a theoretical concept but a practical solution being implemented by innovative companies. As illustrated by the collaborations of Asahi Kasei and Microwave Chemical, and gr3n with Intecsa Industrial, this technology is poised to redefine the recycling industry. By reducing energy consumption and greenhouse gas emissions, microwave technology offers a promising path towards a sustainable future.