3D Printing Waste Repurposed for Injection Molding.

CRP, a well-established firm in the selective laser sintering (SLS) 3D printing field, has made an unexpected yet innovative leap into sustainable injection molding. They’ve introduced a new product, Windform XT 2.0 IMG, which brilliantly repurposes wasted materials from the SLS process, creating a sustainable and eco-friendly solution in injection molding.

While this may initially seem like an unconventional move, a closer look reveals the underlying motivations.

What sets this material apart is its unique approach to addressing the wastage associated with the SLS process. By repurposing unsintered Windform XT 2.0 powder that no longer meets CRP’s high quality standards for professional 3D printing, the company has created a sustainable solution. This re-granulated carbon-reinforced PA12 material allows for a significant reduction in carbon footprint while minimizing material waste.

Windform XT 2.0 IMG not only offers environmental benefits but also delivers impressive performance. With properties such as high stiffness, shock resistance, and exceptional detail accuracy, it meets the stringent requirements of demanding industries such as automotive, transportation, agriculture, and robotics.

By leveraging Windform XT 2.0 IMG, companies can reduce their environmental impact by minimizing material waste and significantly lowering carbon emissions. This innovative approach aligns with the growing need for sustainable manufacturing materials in various industries.

Additional Comments

Selective Laser Sintering (SLS) is a popular 3D printing method that has revolutionized the production of complex and custom parts. However, it’s not without its waste generation. This stems primarily from the nature of the process itself. SLS uses a high-power laser to fuse small particles of plastic, metal, ceramic, or glass powders into a mass that has a desired 3D shape. The laser selectively fuses the powdered material by scanning cross-sections generated from a 3D digital description of the part on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

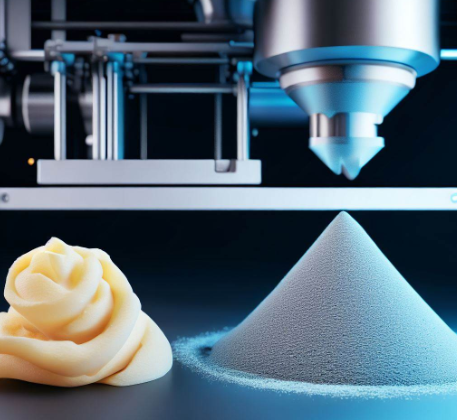

The result of this process is a significant amount of unused powder after each print, also known as “unsintered powder”. This happens because only the exact amount of powder needed to form the desired object is fused, while the rest is left in the bed unutilized. While it is possible to recycle some of this unused powder for use in future prints, a portion of it deteriorates in quality after being exposed to heat and can no longer meet the high standards required for SLS 3D printing. This deteriorated powder forms the waste from SLS 3D printing. The accumulation of this waste material presents significant environmental and disposal challenges, thus creating a need for innovative and sustainable solutions like CRP’s Windform XT 2.0 IMG. 3D Printing waste (Unsinterd powder) repurposed for injection molding grade.

More information

CRP Technology